Granular Activated Carbons (GAC)

Xingyuan produces various of activated carbon.

----apricot granular activated carbon

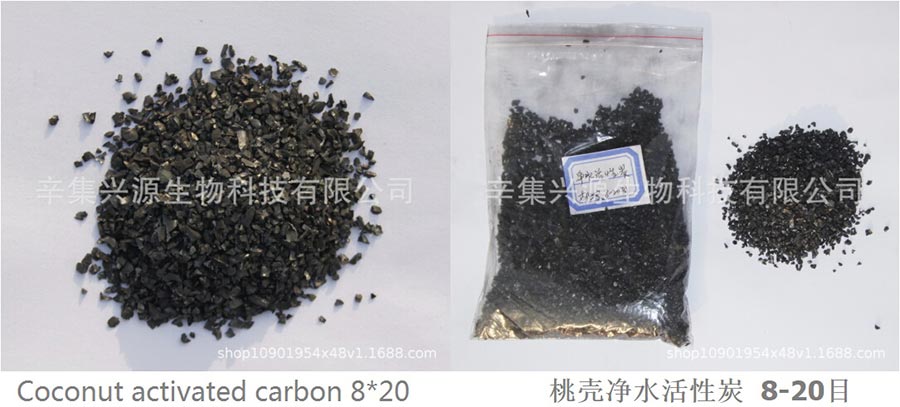

----coconut granular activated carbon

----dates granular activated carbon

----palm granular activated carbon

Early made from wood, hard fruit shells or animal bones by carbonization and activation, and then converted to coal by crushing, forming, or using uniform coal particles through carbonization and activation production. Activated carbon is irregularly arranged in structure due to the microcrystalline carbon, and there are pores between the cross-connects. During activation, carbon structure defects will occur, the packing density is low, and the specific surface area is large. The specific surface area of ordinary activated carbon is between 500 and 1700 m2 / g.

Classification of activated carbon:

By source of raw materials

1. Wood activated carbon

2. Animal bone/blood activated carbon

3. Mineral raw material activated carbon

4. Activated carbon of other raw materials

5. Recycled activated carbon

According to appearance shape

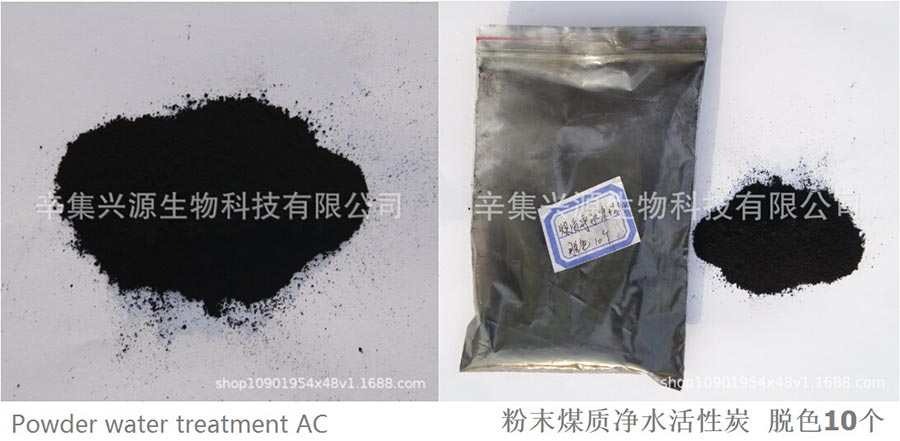

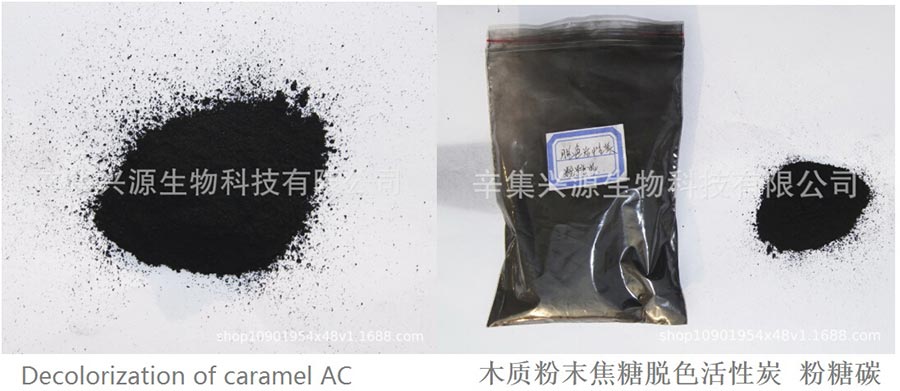

1. Powdered activated carbon

2. Granular activated carbon

3. Activated carbon with unshaped particles

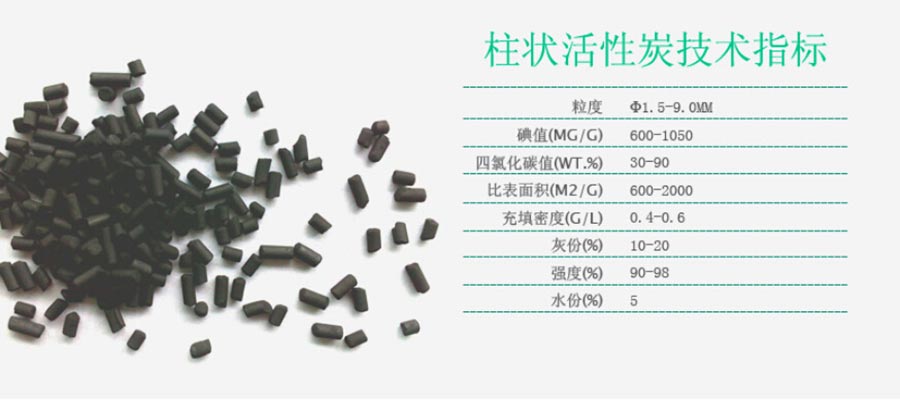

4. Cylindrical activated carbon

5. Spherical activated carbon

6. Other shapes of activated carbon

The constituent elements of activated carbon:

In terms of elemental composition, activated carbon is composed of more than 80% -90% carbon, which is why activated carbon is a hydrophobic adsorbent. In addition to the I carbon element, activated carbon also contains two types of admixtures: one is chemically combined elements, mainly oxygen and hydrogen, these elements are left in the carbon due to incomplete carbonization, or during the activation process, Exogenous non-carbon elements are chemically combined with the surface of activated carbon. For example, when activated with water vapor, the surface of activated carbon is oxidized or oxidized with water vapor. Another type of admixture is ash, which is the inorganic part of activated carbon and consists of several elements of activated carbon. Activated carbon experts can see that activated carbon also contains a small amount of hydrogen and oxygen, and zinc chloride activated carbon contains a small amount of CI.

Xingyuan Industry created the first granular activated carbon (GAC) from apricot charcoal in the 1995s and has staked a position of global industry leadership ever since.

Today, more than 30 years after its founding, remains on the cutting edge of innovation, offering an exceptional range of granulated activated carbon (GAC) and reactivated carbon formulations engineered specifically for the purification of water, air, liquids, and gases. Xingyuan is proud to provide products that help make pure water and clean air for a better world.

Granular activated carbon is defined as the activated carbon being retained on a 50-mesh sieve. Xingyuan produces GACs with a variety of materials, methods, and degrees of activation to produce activated carbons designed to meet and exceed the demands of a wide array of applications.

From water treatment to gas phase applications, and from the purification of other aqueous and organic liquids to the treatment of cane sugar liquors and much more — Xingyuan offers a wide array of custom-engineered granular activated carbons for a broad range of manufacturing process and environmental applications.

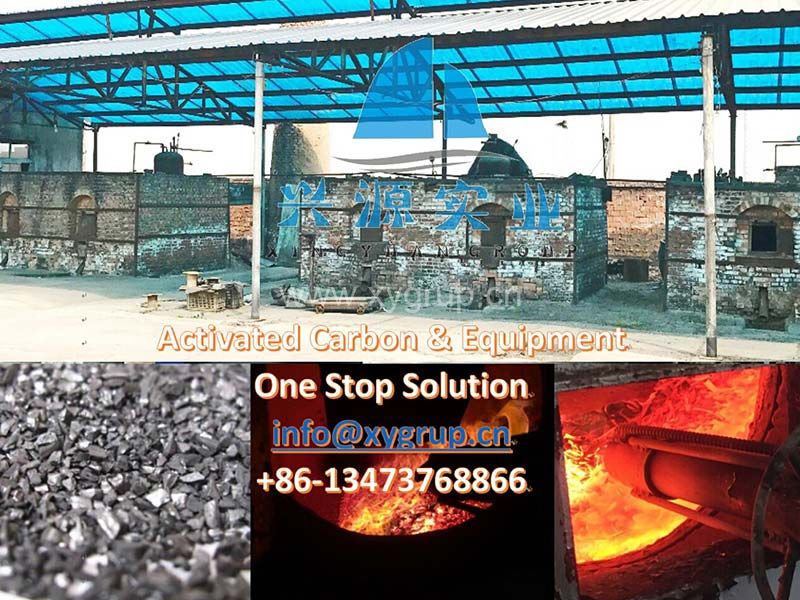

Xingyuan Activated Carbon Factory Equipment

From 1990, Charcoal as Xingyuan Group first business, now already almost 30 years history, from 1997, Xingyuan begin to produce activated carbon as development for charcoal, now Xingyuan has carbonizing furnace 4set, Activation Rotary Kiln 6 set, and Upright Kiln 3 set, factory take land more than 70000square meter, yearly capacity for activated carbon more than 6000tons, become the first top three in North China carbon active enterprise.

Beginning from 2008, Xingyuan begins import coconut shell charcoal raw material from Indonesia, Philippine, Vietnam, etc. southeast countries, import wood charcoal from South Africa countries, keep a good relationship with suppliers till to now.

Based on the years of technology and manufacturing experience, Xingyuan activated carbon export to Japan, S.Korea, and other countries, get more focus from clients and a good reputation.

|  |

| Activated carbon Rotary Kiln | |

|  |

| Activated carbon upright kiln | |

|  |

| Activated carbon Rake furnace / Harrow Furnace | |

|  |

| Activated carbon Slep Kiln Activated carbon Srep Kiln | |

The activated carbon we supply is beautiful in price and high in quality. Welcome to contact us!

The adsorptive capacity of granular activated carbon (GAC) makes it ideal for removing a variety of contaminants from water, air, liquids and gases. GAC is also an environmentally responsible product that can be reactivated through thermal oxidation and used multiple times for the same application.

By varying manufacturing conditions, internal pore structures are created by imparting unique adsorption properties specific to each product type. The choice of product for a specific application will vary due to differing impurities and proprietary process conditions.

Xingyuan brings unmatched expertise in developing granular activated carbons. That means whatever your granular activated carbon need, Xingyuan has a product engineered specifically to provide a better solution.

| ||

| 4×6 (4.75 x 3.35 mm) | 8×16 (2.36 x 1.18 mm) | 18×40 (1.00 x 0.425 mm) |

| 4×8 (4.75 x 2.36 mm) | 10×18 (2.00 x 1.00 mm) | 20×50 (0.85 x 0.300 mm) |

| 4×10 (4.75 x 2.00 mm) | 12×20 (1.70 x 0.85 mm) | 30×60 (0.60 x 0.250 mm) |

| 6×12 (3.35 x 1.70 mm) | 12×30 (1.70 x 0.60 mm) | 30×70 (0.60 x 0.212 mm) |

| 6×14 (3.35 x 1.40 mm) | 12×40 (1.70 x 0.425 mm) | 50×100 (0.300 x 0.150 mm) |

| 6×16 (3.35 x 1.18 mm) | 14×30 (1.40 x 0.60 mm) | 50×200 (0.300 x 0.075 mm) |

| 8×14 (2.36 x 1.40 mm) | 18×35 (1.00 x 0.50 mm) | 60×200 (0.250 x 0.075 mm) |

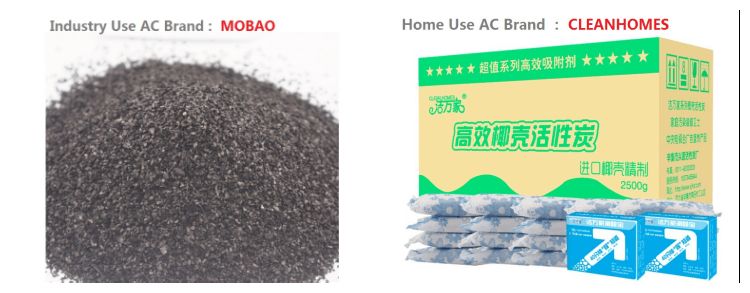

Different type of Activated Carbon By Xingyuan Industry

| 1 |  |

| Apricot activated carbon for gold mining use | |

| 2 |  |

| Gold mine activated carbon by apricot based | |

| 3 |  |

| Coconut activated carbon coconut activated charcoal | |

| 4 |  |

| Water treatment activated carbon | |

| 5 |  |

| Drinking water activated carbon /Activated carbon for water purification | |

| 6 |  |

| Water purify activated carbon activated carbon for water | |

| 7 |  |

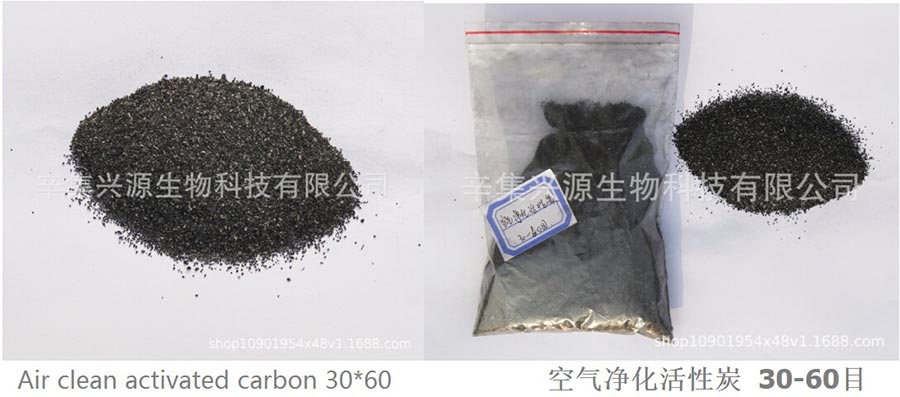

| Carbon activated Activated carbon for air purification | |

| 8 |  |

| Granular activated carbon mesh size activated carbon GAC | |

| 9 |  |

| Activated carbon for filter Activated carbon granular | |

| 10 |  |

| Powder activated carbon activated carbon powder | |

| 11 |  |

| Sugar use activated carbon PAC | |

| 12 |  |

| Extruded activated carbon Pellets activated carbon | |

| 13 |  |

| Activated carbon pellets Coal based pellets activated carbon | |

| 14 |  |

| Coal activated carbon Coal based activated carbon | |

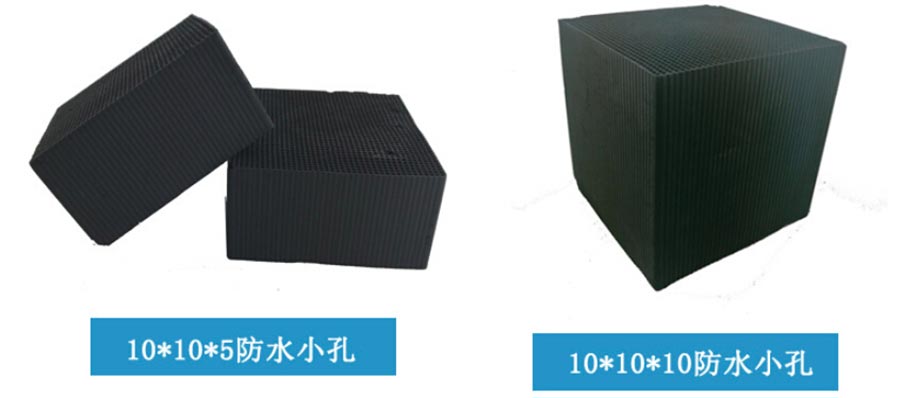

| 15 |  |

| Honeycomb activated carbon Gas honeycomb activated carbon |

· Water treatment

· Air & Gas treatment

· Chemicals & Pharmaceutical

· Food & Beverages

· Gold Recovery

Granular Activated Carbon(Gas & Vapor Phase)

Grade | Standard particle size (mesh) | Characteristics | Typical application |

General natural gas adsorption Use | ○ 4 ~ 5.5 | 1: The activated carbon sizes can be selectable | A: Cigarette filter |

4 ~ 7.5 | |||

5.5 ~ 7.5 | |||

○ 6.5 ~ 10 | |||

○ 7.5 ~ 14 | |||

10 ~ 18 | |||

General natural gas adsorption Use | 2.5 ~ 5.5 | 1. Very effective recycling is possible as the | A: Removal of general toxic and noxious- odor gases. |

Solvent Recovery Use | ○ 4 ~ 5.5 | 1: Macropore and micropore charcoal are | A: Solvent Recovery |

5.5 ~ 7.5 | |||

Catalyst Carrier Use | 10 ~ 30 | 1: High purity and hardness facilitates long-term | A: Carrier for synthetic reaction of vinyl acetate, |

22 ~ 42 | |||

30 ~ 60 | |||

For gas separation purification | ○ 4 ~ 5.5 | 1: Excellent gas separation ability due to the highly developed micropores. | A: Adsorption of gold and phenol in separation, and purification in liquid phase, such as hydrogen, carbon dioxide, and carbon monoxide. |

○ 6.5 ~ 10 | |||

Desulfurization gas use | 4 ~ 5.5 | 1: Activated carbon can be used for | A: Removal of sulfurous acid gas and hydrogen |

For solvent collection | 7.5 ~ 26 | 1: High-performance macropore charcoal | A: Collection of transpiration gasoline for |

Granular activated carbon (Liquid & water phase)

| Grade | Standard particle size(mesh) | Characteristics | Typical application |

| For water purification | 10 ~ 30 | 1: Coconut shell activated carbon has good characteristics, high purity, and sufficient hardness. 2: No fine particles generated during use. 3: Can be reused by regeneration. | A: Removal of musty smell in tap water, COD compounds, and THM B: Removal of ABS in water, phenol, foul odor and taste substances, and coloring matter C:Dechlorination of drinking water, pure water, or industrial water, removal of organic matter D:Water purifier, chemical compounds for water purification E: Tertiary treatment of sewage water and waste water from industrial use |

| 18 ~ 42 | |||

| 30 ~ 60 | |||

| For liquid phase purification | 10 ~ 30 | 1: Coconut shell activated carbon with high adsorption capability and purity 2: Good for adsorption of minor components due to well-developed micropores. 3: Can be reused by regeneration. | A: Decolorization and purification of industrial chemicals, intermediates or F&B products. B: Treatment of minor organic impurities in liquid phase |

| 18 ~ 42 | |||

| 30 ~ 60 | |||

| For decolorization of liquid phase | 10 ~ 30 | 1: The macro pores of this carbon are suited for removal of colors. 2: Especially good in decolorization of highly concentrated solution. 3: Both caustic soda and baking recycling are possible. | A: Decolorization in food industry, such as amino acid, brewing, monosodium glutamate, glucose, sugar, syrup, gelatin, etc. B: Decolorization and purification of industrial chemicals, intermediates or F&B products. C: Decolorization of cleaning solvent D: Decolorization of waste water |

| 16 ~ 42 | |||

| For general water processing and decolorization | 10 ~ 30 | 1: Very well-developed micro- to meso-scale pores of this coal-based activated carbon provide excellent adsorption speed and adsorption capacity. 2: Can be used very efficiently by recycling. | A: Removal of COD and decolorization of sewage water and waste water B: Removal of COD compounds and humic substances in tap water C: Decolorization and purification in production processes of various products D: Preprocessing of factory water and pure water processing E: Decolorization in foods industry, such as glucose, sugar, syrup, glycerin, etc. F: Decolorization and purification of industrial chemicals, intermediates or F&B products. |

| 18 ~ 42 | |||

| For processing general water | 7.5 ~ 18 | 1: As it has good surface hardness and abrasion resistance, recycling with high efficiency is possible. 2: Due to its spherical shape, adding to and removal from the adsorption tower can be performed easily. 3: Little fine powder is produced, and the equipment can start operation immediately. | A: Removal of COD and decolorization of sewage water and waste water B: Removal of COD compounds and humic substances in tap water C: Decolorization and purification in production processes of various products |

| 10 ~ 30 |

Water Treatment

Water. One of the world's most precious resources for drinking, irrigation or industrial processes. The supply of clean, fresh water continues to be more and more constrained as populations rise and water demands grow on our planet. Activated carbon is one of the best technologies available for improving water quality.

Water is a vital global resource, and activated carbon is widely used in many processes and industries where water needs to be purified.

Perhaps the best known application for activated carbon is the purification of drinking water. Indeed, in most developed countries, almost all municipal drinking water is filtered through activated carbon, as part of a multi-step purification process.

Applications for activated carbon in water purification include the following:

– Municipal drinking water treatment

– Point-of-use (POU) and point-of-entry (POE) filters

– Industrial process water, e.g. breweries, food, power plants, chemicals production,…

– Groundwater and soil remediation

– Industrial wastewater

– Municipal wastewater

– Landfill leachate

– Aquarium filters

– Swimming pool filtration

Depending on the exact application, activated carbons remove a wide range of unwanted chemicals and pollutants, including:

– Colour, taste and odour compounds in drinking water, such as Geosmin and MIB (2–Methylisoborneol)

– Dechlorination in POU filters, process water applications, swimming pools and aquaria filters

– Trace contaminants such as pharmaceuticals, herbicides, pesticides and other persistent organic pollutants (POPs) from municipal water streams.

– Various organic pollutants, such as the BTEX group, PFOS/PFOA and hydrocarbons, from groundwater in remediation projects, or from leachates.

Xingyuan supplies a wide range of product and services for the treatment of water. Powdered activated carbons (PAC) are used in batch treatment processes, whereas granular (GAC) grades are generally used in fixed filter beds, with the water passing through the filtration medium.

Air & Gas Treatment

The purity of air on our planet is of vital importance to us all. Whether you are working to meet emission regulations to protect the environment and/or human health, reduce nuisance odors, or produce ultrapure gas streams, Xingyuan provides the exact carbon to address your need.

Activated carbons are used extensively in the gas phase for the removal of a variety of unwanted contaminants, such as volatile organic compounds (VOCs) and odour-causing molecules. In China, the Government’s 2019 Clean Air Strategy will focus a great deal of attention on this issue, and Xingyuan Activated Carbons stands ready to assist in the supply of air purification solutions.

VOCs, typically from industrial processes such as chemical/pharmaceutical production, petrochemical tank venting, spray booths and soil remediation projects, include compounds such as acetone, benzene, styrene, toluene and xylene.

Odour control systems make use of impregnated activated carbons to remove compounds such as hydrogen sulfide (H2S), mercaptans, DMS and ammonia (NH3).

Industrial gas streams may require the removal of trace levels of various contaminants such as VOCs or, in the case of natural gas, heavy metals like mercury and cadmium.

In the oil and gas industry, specialised activated carbons are used as catalyst supports for mercaptan oxidation in the so-called Merox process. Mercaptans are removed from hydrocarbon streams by converting them to liquid disulfides.

For personal protection applications, such as respirators and escape hoods, carbons are used to remove a range of harmful or poisonous gaseous compounds.

Activated carbons can also be used in cigarette filters for the removal of some of the smoke's constituents, in order to improve the taste experience.

Chemicals & Pharmaceutical

Purity is essential in the production of pharmaceutical products. This applies to all stages, from raw materials to intermediates to final product. The unique properties of specific activated carbons from Xingyuan provide superior removal of colour compounds, odour compounds, proteins and other contaminants that could be present in the raw materials, or that form during production.

Activated carbons are used extensively for purification purposes in the production of a wide range of industrial chemicals and pharmaceutical compounds. Typical applications include the purification of amino acids, biodiesel, glycerine, mineral acids and active pharmaceutical ingredients (APIs).Solvent recovery is also an important application for activated carbon, either in the chemical/petrochemical industry or in printing and ink/dye production facilities.

Other uses for activated carbons in the petrochemical industry include amine and glycol purification, removing contaminants from gas scrubber systems.

Activated carbons are used either in a powder (PAC) form, and dosed in a batch process, or used in a granular form (GAC) in a fixed bed adsorber. As well as being useful for the main manufacturing process, carbons may also be used for the recovery of off-spec materials, or for the improvement of product purity levels to allow the sale of a higher-grade end-product.

Food & Beverages

Beverage makers rely on activated carbon to remove bad tastes and odors and help ensure the long-term stability of their products. We manufacture Activated Carbon products that are used to improve the quality of beverages ranging from water to fruit juices to distilled liquor so that beverages look good, smell good and taste good.

Activated carbons have long been used in the food and beverage industries for the purification of liquid and gas phase process streams. Their main purpose is the removal of colour, taste and odour, as well as any other organic trace contaminants.

Typical examples include the following:

– Sweetener purification – cane sugar, glucose and syrups.

– Food-grade acids, e.g. citric acid, produced via a fermentation process.

– Purification of ethanol for use in alcoholic beverages.

– Removal of tannins and other impurities in the wine growing industry.

– Purification of carbon dioxide (CO2) gas produced in breweries, prior to its re-use in food-grade applications.

– A highly purified form of PAC is used as the black food colourant E153

Gold Recovery

Highly activated carbon is used in the dissolved gold recovery process, either by introducing it directly into the CIL (carbon-in-leach) tanks or into separate CIP (carbon-in-pulp) tanks after leaching.The activated carbon adsorbs the dissolved gold from the leach slurry thereby concentrating it onto a smaller mass of solids. The carbon is then separated from the slurry by screening and subjected to further treatment to recover the adsorbed gold.

Xingyuan Activated Carbons has extensive operational and commercial experience in the supply of specialised grades of activated carbons into the precious metal recovery industry.

Activated carbons are used to recover gold from cyanide solutions, which are percolated through gold-containing ores.

Three main technologies exist for recovering gold from cyanide leachate solution:

– Carbon-in-Pulp (CIP)

– Carbon-in-Leach (CIL), includes 'Heap Leach'

– Carbon-in-Column (CIL)

Xingyuan Activated Carbons supplies a range of carbons for the gold mining industry, which independent testing, by leading academic institutions, has shown to offer exceptional performance. Our products are characterised by the following properties:

– High rates of gold loading and elution

– Good resistance to mechanical attrition

– Stringent particle size distribution

– minimal undersized material

– Low platelet concentrations

– Good reactivation performance

Soil Remediation

Activated carbon is produced when materials with high carbon concentrations, such as coal, wood, peat, or even coconut shell, undergo special treatment processes that expose them to extremely high temperatures without burning them. The result is a porous, highly adsorptive substance that binds easily with organic toxins. When mixed into contaminated soil or sediment, the activated carbon draws dioxin to it and sequesters it.

Cosmetics

Around the world, many different traditional medicine practitioners use activated charcoal powder made from coconut shells to treat soft tissue conditions, such as skin infections. Activated charcoal may have an antibacterial effect by absorbing harmful microbes from wounds. Several are available commercially. Activated charcoal–when used in a face mask–binds to dirt and helps pull it out of your pores, making them less visible (it's the oil and dirt that makes them appear bigger). This leaves your face feeling fresh.