Xingyuan supply Organoclay & Activated Clay

----oil and water use organoclay

----water use Activated Clay.

|  |

Organoclay & Activated Clay is a modified clay mineral designed for use as a filter media in process and wastewater treatment. When used alone, OrganoClay removes oil at 700% the rate of activated carbon. When used as a pre-treatment for activated carbon in applications involving oil and grease removal, OrganoClay removes the oil and grease effectively, allowing the activated carbon to remove the soluble organic compounds more efficiently.

--Xingyuan Activated Carbon Factory Equipment

From 1990, Charcoal as Xingyuan Group first business, now already almost 30 years history, from 1997, Xingyuan begin to produce activated carbon as development for charcoal, now Xingyuan have carbonizing furnace 4set, Activation Rotary Kiln 6 set, and Upright Kiln 3 set, factory take land more than 70000square meter, yearly capacity for activated carbon more than 6000tons, become the first top three in North China carbon active enterprise.

Beginning from 2008, Xingyuan begin import coconut shell charcoal raw material from Indonesia, Philippine, Vietnam etc. south east countries, import wood charcoal from South Africa countries, keep the good relationship with suppliers till to now.

Based on the years of technology and manufacturing experience, Xingyuan activated carbon export to Japan, S.Korea and other countries, get more focus by clients and good reputation.

|  |

| Activated carbon Rotary Kiln | |

|  |

| Activated carbon upright kiln | |

|  |

| Activated carbon Rake furnace / Harrow Furnace | |

|  |

| Activated carbon Slep Kiln Activated carbon Srep Kiln | |

OrganoClay - A Cost Saving Filtration Media

When used alone, OrganoClay removes oil at 700% the rate of activated carbon and will reduce your operating costs by 50% or more. When used as a pre-treatment for activated carbon in applications involving oil and grease removal, OrganoClay removes the oil and grease effectively, allowing the activated carbon to remove the soluble organic compounds more efficiently.

OrganoClay Increases the Efficiency of the Treatment Process

The quarternary amine-treated clay pellets have the ability to capture 50 – 60% of their weight in oil, grease and other low solubility organic compounds. Used upstream from activated carbon or downstream of other oil removal processes, OrganoClay optimizes the overall system performance and reduces costs.

Stand Alone

OrganoClay outperforms anthracite, GAC, and all other filter media technologies in stand-alone applications for the removal of higher molecular weight hydrocarbons.

Post Treatment

OrganoClay may be applied downstream of oil/water separators, DAF systems, clarifiers, sand filters, and other physical/chemical separation systems.

Application

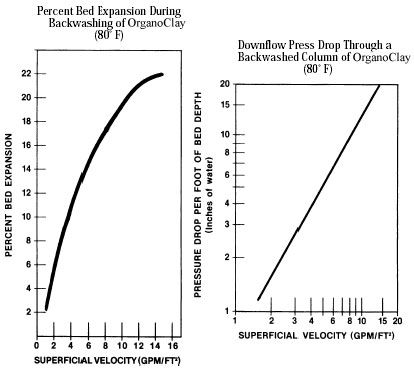

OrganoClay is designed for column operation. The media should be placed in appropriately sized fluid contactor vessels in the same manner as granular activated carbon (GAC). OrganoClay needs to be wetted and deaerated with clean water for a minimum of 1 hour prior to the introduction of contaminants in order to prevent fluid channeling within the media bed.

Pre-Treatment

OrganoClay may be used to pre-treat the influent of GAC filters, reverse osmosis units, ultra filtration units, and other related systems where less soluble, higher molecular weight hydrocarbons tend to cause plugging, fouling, and equipment contamination.

Dosage

The amount of OrganoClay required will vary depending on contaminant concentration and type, contact time, and fluid temperature. Generally, contaminants with lower concentrations and solubilities, longer contact times, and moderate fluid temperatures are preferred.

Storage and Handling

Store in a dry place. Avoid extreme temperatures. Avoid breathing dust.

Hydrocarbon Removal with OrganoClay

Organoclay completely removes free hydrocarbons from wastewater and also removes dissolved hydrocarbons including benzene, toluene, ethylbenzene, and xylene (BTEX). When used in conjunction with a polishing stage of granular activated carbon, Modified Clay Media removes dissolved and free hydrocarbons to levels well below current water quality standards.

OrganoClay product can be used to effectively remove oil and other hydrocarbons from water where traditional oil-water separators have had limited success. The product does not absorb hydrocarbons, but rather adsorbs them, which leaves no byproduct from the process. In the adsorbtion process, the quaternary amines create organic pillars between the clay platelets that increase the interlamellar distance and facilitate the formation of a hydrocarbon partition.

| Sample Constituent | Projected: Before | Projected: After | Result: % Reduction | Source Type |

| Acenaphthene | 5,580.0000 | BDL | 99.99% | Creosote Plant |

| 0.1500 | 0.0005 | 99.67% | Wood Processing | |

| Acenaphthylene | 0.0067 | ND | 99.99% | Wood Processing |

| Aluminum | 0.100 | 0.0200 | 80.00% | Chemical Plant |

| Ammonia Nitrogen | 245.0000 | 21 | 91.43% | Paper Mill 2 |

| Anthracene | 3.9580 | ND | 99.99% | Carbon Black Plant |

| 3,650.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0134 | ND | 99.99% | Wood Processing | |

| Arsenic | 2.6200 | 0.1220 | 95.34% | Oil Production |

| 0.2130 | 0.0130 | 93.90% | Creosote Plant | |

| Benzene | 9.8000 | 0.2300 | 97.65% | Natural Gas Well |

| Benz (a) Anthracene | 1,170.0000 | BDL | 99.99% | Creosote Plant |

| 0.0001 | ND | 99.99% | Wood Processing | |

| Benzo (b) Fluoranthene | 0.0001 | ND | 99.99% | Wood Processing |

| Benzo (a) Pyrene | 0.0360 | ND | 99.99% | Carbon Black Plant |

| Benzo (g,h,i) Perylene | 0.0380 | ND | 99.99% | Carbon Black Plant |

| BOD's | 244 | 11 | 95.49% | Firefighting Academy |

| 1,100.0000 | 9 | 99.18% | Laundry Service | |

| 211,000.0000 | 533 | 99.75% | Paper Mill 3 | |

| 113,400.0000 | 849 | 99.25% | Creosote Plant | |

| 23,689.0000 | 2,133 | 91.00% | Paper Mill 1 | |

| BTEX | 1.0000 | 0.0270 | 97.30% | Shipyard |

| 20.4900.0000 | ND | 99.99% | Firefighting Academy | |

| Cadmium | 0.0220 | BDL | 99.99% | Laundry Service |

| 4-Chloro-3-Methylphenol | 26.0000 | ND | 99.99% | Process Coolant |

| Chromium | 0.0780 | ND | 99.99% | Laundry Service |

| 2.0200 | 0.0080 | 99.60% | Creosote Plant | |

| 24.8000 | 4.3100 | 82.62% | Braking Systems | |

| Chrysene | 10,7000.0000 | BDL | 99.99% | Creosote Plant |

| 0.0001 | ND | 99.99% | Wood Processing | |

| Cobalt | 1.5200 | 0.0300 | 98.03% | Chemical Plant |

| COD's | 3,340.0000 | 113 | 96.62% | Firefighting Academy |

| >23,000.0000 | 458.0000 | 98.01% | Paper Mill 3 | |

| 87,200.0000 | 949.0000 | 98.91% | Paper Mill 2 | |

| Copper | 4.0000 | 0.0220 | 99.45% | Shipyard 1 |

| 0.2520 | BDL | 99.99% | Laundry Service | |

| 1.5600 | 0.0530 | 96.60% | Creosote Plant | |

| 1,1 Dichloroethane | 0.0150 | ND | 99.99% | Groundwater |

| 0.0094 | ND | 99.99% | Groundwater | |

| 1,2 Dichloroethene | 1.5000 | ND | 99.99% | Groundwater |

| 1,4 Dioxane | 726.5000 | 126 | 82.66% | Plastics Mfr. |

| Ethylbenzene | 1.6000 | 0.0073 | 99.54% | Natural Gas Well |

| Fluoranthene | 4.3930 | ND | 99.99% | Carbon Black Plant |

| 95,400.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0057 | 0.0001 | 97.44% | Wood Processing | |

| Fluorene | 59,900.0000 | BDL | 99.99% | Creosote Plant |

| 0.0789 | ND | 99.99% | Wood Processing | |

| Gasoline Range Hydrocarbons | 1.8800 | ND | 99.99% | Process Coolant |

| Lead | 2.0000 | 0.0110 | 99.45% | Shipyard 1 |

| 4.1800 | BDL | 99.99% | Laundry Service | |

| Manganese | 5.7500 | 0.4000 | 93.04% | Chemical Plant |

| Mercury | 0.0018 | ND | 99.99% | Oil Production |

| 2-Methylnaphthalene | 6.1000 | ND | 99.99% | Creosote Plant |

| Motor Oil | 310 | ND | 99.99% | Process Coolant |

| Naphthalene | 1.0000 | ND | 99.99% | Shipyard 1 |

| 21,400.0000 | BDL | 99.99% | Creosote Plant | |

| 0.6830 | 0.0008 | 99.89% | Wood Processing | |

| Nickel | 2.0000 | 0.1600 | 92.00% | Shipyard 1 |

| 0.0200 | ND | 99.99% | Oil Production | |

| 0.0840 | BDL | 99.99% | Laundry Service | |

| Oil and Grease | 200 | ND | 99.99% | Shipyard 1 |

| 488 | ND | 99.99% | Tank Cleaning | |

| 289,000.0000 | 3.4600 | 99.99% | Laundry Service | |

| 147,000.0000 | 3.4600 | 99.99% | Paper Mill 3 | |

| 68,800.0000 | BDL | 99.95% | Creosote Plant | |

| 3,360.0000 | 1.6600 | 97.78% | Paper Mill 1 | |

| 2,050.0000 | 45.6000 | 99.99% | Braking Systems | |

| 1.0000 | ND | 99.99% | Wood Processing | |

| PCP (Pentachlorophenol) | 4,630.0000 | BDL | 99.99% | Creosote Plant |

| 2.4500 | 0.1300 | 94.69% | Wood Processing | |

| Phenanthrene | 15,900 | BDL | 99.99% | Creosote Plant |

| 0.0888 | 0.0001 | 99.90% | Wood Processing | |

| Phenolics (recoverable) | 2.0000 | 0.1550 | 92.25% | Shipyard 1 |

| Phosphourus | 3.5000 | 0.2000 | 94.29% | Chemical Plant |

| Pyrene | 16.1570 | ND | 99.99% | Carbon Black Plant |

| 42,700.0000 | BDL | 99.99% | Creosote Plant | |

| 0.0028 | 0.0001 | 96.19% | Wood Processing | |

| TCE (Trichloroethene) | 0.1800 | BDL | 99.99% | Landfill Groundwater |

| 2.8000 | ND | 99.99% | Groundwater | |

| TCE (Trichloroethylene) | 250.0000 | 2.2000 | 99.12% | Pesticide Mfr. |

| TOC (Total Organic Compounds) | 86,000.0000 | 1,370 | 98.41% | Paper Mill 1 |

| Toluene | 26.0000 | 0.0200 | 99.92% | Natural Gas Well |

| TPH (Total-Petroleum Hydrocarbons) | 50.0000 | ND | 99.99% | Firefighting Academy |

| Total Phosphorous | 132.0000 | 3.2 | 97.58% | Paper Mill 2 |

| TSS's | 93.0000 | 10 | 89.25% | Firefighting Academy |

| 500.0000 | 9 | 98.20% | Laundry Service | |

| 27,400.0000 | 43 | 99.84% | Paper Mill 2 | |

| 57,250.0000 | 58 | 99.90% | Creosote Plant | |

| Vinyl Chloride | 0.2600 | ND | 99.99% | Groundwater |

| Xylene (m & p) | 14.000 | 0.0076 | 99.95% | Natural Gas Well |

| Xylene (o) | 3.5000 | 0.0013 | 99.96% | Natural Gas Well |

| Zinc | 4.0000 | 0.7430 | 81.43% | Shipyard 1 |

| 0.0460 | 0.0150 | 67.39% | Oil Production | |

| BDL | 99.99% | Laundry Service |

Bulk Density 46 lbs./cu.ft. Specific Gravity 1.5-2.5 pH Range 2-12 Temperature Range 33-180ºF Flash Point +400ºF Contact Time 3 minutes actual retention time 9 minutes EBCT (at 80% fill) Typical Usage Recommendations Typical Applications:

- Removal of Oil & Grease

- insoluble hydrocarbons from wastewater or ethylene glycols