Xingyuan Slep Activated Carbon Kiln/ Srep Activated Carbon Kiln

---Russia technology activated carbo srep kiln

---Stable with high Iodine and MB value quality AC

---Most stable running

---Xingyuan Biomass Equipment Brand---

Explanation for Srep/Slep activated carbon Kiln:

1- The Srep activated carbon kiln is Russia technology kiln, main for coal based and wood based activated carbon production.

2- According to the size, separated into 166 and 288 chanel.

This is a type of more big capacity kiln for coal based activated carbon and wood activated carbon production line. whole body build by the fire bricks and normal bricks.

SLEP KILN (furnace SLEP) is an activation method using water vapor and flue gas (CO2) as the activator, alternately activating method, carbon particles can be from top to bottom in the furnace during movement of mutually shifting movement were mixed uniformly so good activation effect. Such fuels without external furnace having a furnace long life, stable activation technology, a uniform product quality, good adsorption performance advantages, in terms of product quality, energy consumption, economic efficiency, waste treatment than other forms are activation furnace location, is a process for producing high-quality granular activated carbon over the furnace. 1, a carbonized material feeder car from a top feed tank was added SLEP furnace furnace, by gravity, slowly down along the product path, successively through a preheating zone 1, supplemented with 2 carbonization, activation belt 3, a cooling zone 4, 5 and finally through the lower discharge discharged, the volume of material activated unloader 5 each discharged a fixed value; production cycle is controlled by adjusting the index and product discharge 5, the discharge time interval, the material production cycle time interval was a positive correlation.

Activated carbon Slep/Srep kiln under construction

Finished Activated carbon Slep/srep Kiln

A method for rapid activation SLEP furnace, characterized in that: (1) increase half-heated air into the furnace volume, the heating temperature was subsequently raised by a half furnace 900° C to 950° C; air is added through the air duct by the blower SLEP semi heating furnace, the combustible gas activation resulting combustion generates heat to increase the furnace temperature, the furnace body in a safe range, to adjust the frequency of the blower, blower speed control, to control the amount of air into the control furnace temperature; by adjusting the blower the frequency and size of air valve opening, so that the furnace temperature was controlled at SLEP. 950 0C; (2), changing the air distribution SLEP furnace waste heat boiler location, to improve the utilization efficiency of the exhaust gas, so that the steam production is increased; the furnace exhaust SLEP position with the wind exhaust duct is provided in the middle thereof, using SLEP furnace exhaust heat of preheated air was added to make the waste heat boiler, and then into the combustion furnace exhaust steam SLEP the waste heat boiler, waste heat boiler to avoid temperature drops, the exhaust gas using improved efficiency and steam production, the steam pressure to 0.45MPa; (3), shortening the discharge interval SLEP furnace, the activated time from 72h to 60h or less; due to water vapor Increased steam supply, combined with the activation temperature is increased, greatly increased rate of activation, then according to indicators product discharge interval is gradually shortened, the activated time to less than 60h.

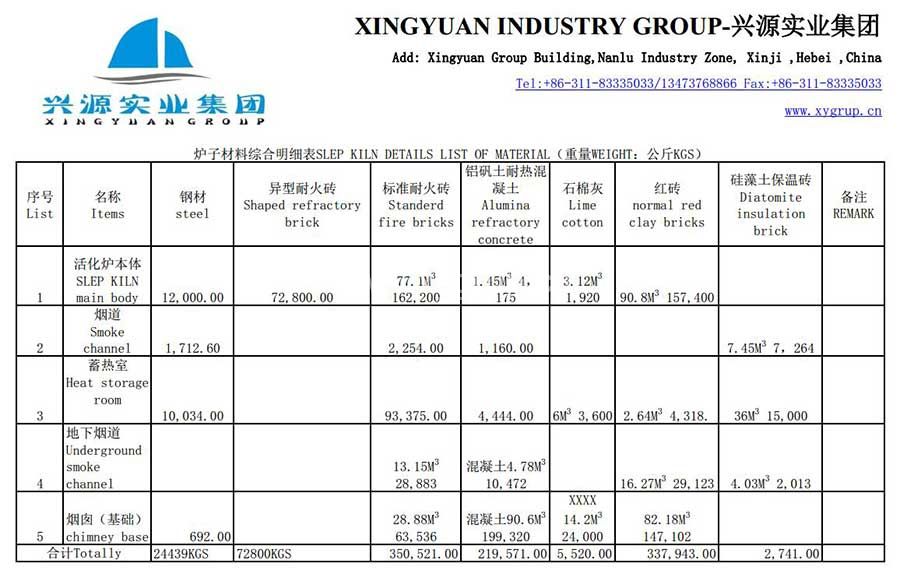

The Srep/Slep Activated Carbon Kiln is built by lot's of special fire bricks, which need special order.

Contact us for more information:

Please contact with us and let us know your simple information and request for our products, we will feedback as soon as possible.