XINGYUAN ACTIVATED CARBON FILTER TANK

Xingyuan machine Brand:

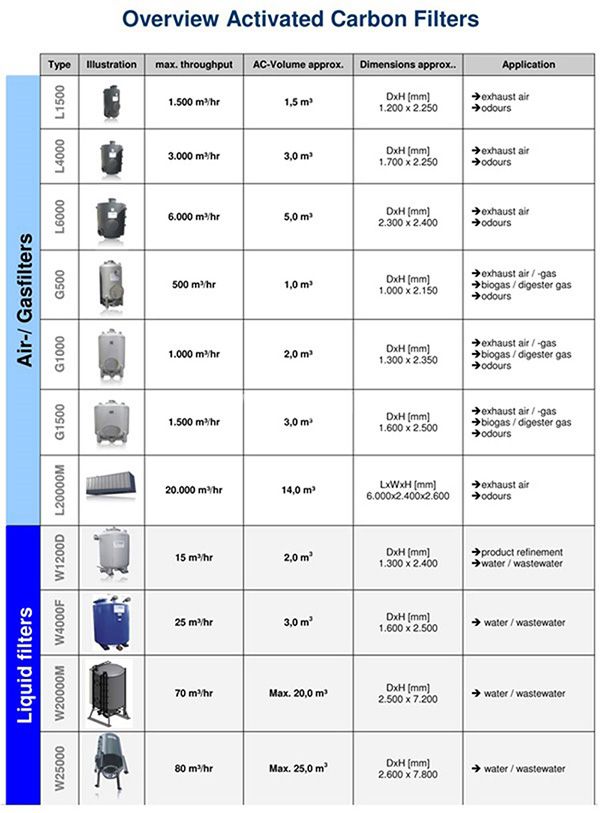

Activated carbon filters function is to adsorb the waste things in the gas phase or liquid phase, and also designed with Mobile or stationary type. So Xingyuan filters tank separated into three type as bellow:

---- Gas-phase adsorbers / Gas-phase activated carbon filters

---- Liquid-phase adsorbers / Liquid-phase activated carbon filters

---- Tailor-made solutions / Moveable activated carbon filter solutions

Rental and Selling of activated carbon filters

Mobile or stationary, for the most diverse applications and a broad range of throughputs.

Our adsorbers / activated carbon filter tank are available in different sizes: from approx. 1m³ up to 14 and 20m³ for our mobile adsorber / activated carbon filter tank systems L20000M and W20000M. All our activated carbon adsorbers / activated carbon filter tank are available as mobile replacement systems.

Additionally, we offer stationary standard adsorbers / activated carbon filter tank and, upon request, supply also tailor-made vessels based on your specification.

With our experience we may offer you logistic and carbon exchange concepts tailored to your specific needs to help you save personnel and operating cost. With our specialized staff and equipment, we take care for quick and smooth exchange of the spent carbon on-site.

All adsorber / activated carbon filter tank types offered by us are available either for sale or to rent. Our standard adsorber / activated carbon filter tank vessels are usually available within a few days.

Gas-phase adsorbers / activated carbon filter tank

Used in the most diverse gas and air cleaning applications such as:

· control of emissions from production processes and manufacturing operations

· odour abatement in sewage treatment plants

· soil remediation, groundwater rehabilitation and treatment of landfill leachate to remove volatile organic compounds using either temporary mobile adsorbers or stationary adsorbers as part of an integrated treatment system

· treatment of biogas and sewage gas frequently containing high concentrations of hydrogen sulphide (H2S) and organic silicon compounds (siloxanes). Activated carbon adsorption of these pollutants helps prevent damage to the downstream gas engines and catalysts and ensures consistent compliance with the emission limits.

Liquid-phase adsorbers / activated carbon filter tank

Used for the most diverse liquid and water treatment applications such as:

· treatment of process effluents from production facilities to ensure compliance with ever more stringent discharge limits,

· drinking water purification, food industry applications, but also for the treatment of aquarium water, applications making exacting demands on the activated carbon filter technology employed and the purity and quality of the activated carbon grades,

· treatment of groundwater and landfill leachate, temporary measures at construction sites, e.g. for site dewatering or waste water treatment or as part of a groundwater treatment plant (e.g. for HCC and AOX removal),

· treatment of the most diverse liquid (inter-mediate) products in the chemical, pharmaceutical and food industries to meet your demanding quality standards, e.g. decolourization of solutions or odour and taste neutralization.

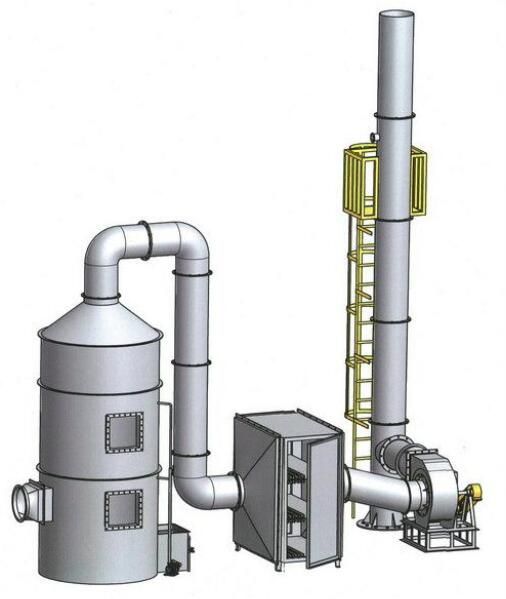

Tailor-made solutions: Individual units or complete systems

Drawing on decades of experience in application technology, we have the knowhow and expertise to deliver solutions for your gas and liquid streams.

We are your competent partner throughout your project from the design via construction through to the commissioning of your activated carbon adsorption system.

You have a problem requiring prompt attention? Then, contact us! Capitalizing on our constantly growing pool of vessels, drums and components, we have the capability to implement our solutions on a fast-track schedule.

Our service portfolio comprises:

· Consulting, process engineering and technical application support

· Design, construction and supply of adsorbers / activated carbon filter tank, associated system components, complete systems through to turnkey solutions

· Modification, upgrades and revamps

· Development of operating and service concepts

· Operation, maintenance and service

· Laboratory

Contact us for more information:

Please contact with us and let us know your simple information and request for our products, we will feedback as soon as possible.